VOL. 39 | NO. 9 | Friday, February 27, 2015

Vanderbilt's Valentine honored for cloaking research

By Amanda B. Womac

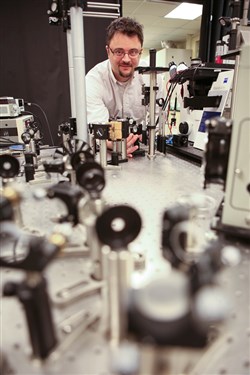

Professor Jason Valentine poses near an infrared microscope in the Nanoscale Optics Lab at Vanderbilt University.

-- Michelle Morrow | The LedgerDr. Jason Valentine, assistant professor of both mechanical and electrical engineering at Vanderbilt University, got his start in cloaking research as a graduate student at the University of California, Berkeley.

“We made the first cloak that worked at optical frequencies,” says Valentine. “It wasn’t quite visible light, but it was sort of a proof of concept that we could make these structures at high frequencies.”

While previous cloaking research focused on the use of microwave frequencies, such as the research completed by Duke University scientists in 2006, Valentine did his research under Dr. Xiang Zhang, professor of mechanical engineering and director of the LBNL Materials Science Division at Berkeley. The team focused on the use of metamaterials in order to create a cloaking device.

In 2008, Time magazine took notice of the work being done by the Berkeley team, selecting, “The Power of Invisibility,’’ as one of the Top 10 Scientific Discoveries of the Year. While the magazine article noted that Berkeley is “one of America’s flakier places,’’ it also pointed out that the work was far from frivolous, describing it as “hard physics.’’

Professor Valentine holds some samples of large area metamaterials formed from structured silicon.

-- Michelle Morrow | The LedgerValentine joined the Vanderbilt faculty in 2010 after completing his Ph.D. in mechanical engineering. That year he was the recipient of the Gold Student Award for his work on optical cloaking from the Materials Research Society, and was in 2014 named one of the top 24 young researchers by the Office of Naval Research for his work on dielectric-based optical metamaterials.

“Metamaterials allow you the flexibility to change the material properties at will, explains Valentine of his work in cloaking.

“With metamaterials, we used nanoscale structuring to change the optical properties of the material so we could bend light around an object. Our research focused on the use of dielectric materials, so the cloak was actually quite transparent.”

Traditional metamaterials are made from metals such as gold. The problem with these traditional metals is they can be absorptive, which can result in a tinted cloak rather than an actual invisible cloak. With dielectric materials, or insulating materials, researchers are able to develop metamaterials that you can see right through.

There are still some real challenges to realizing true invisibility with metamaterials.

“There was a lot of interesting cloaking research going on a while ago, but it sort of died out because of some practical problems in scaling cloaks to a large area,” says Valentine.

“You can design a cloak for a large object, but to make it and actually have it work? That’s another story.”

If researchers could create cloaks on a large scale, there are several practical applications for cloaking.

What if you could remove all the structural blind spots in your car with an invisibility cloak? Interested in owning a home with a 360 degree view of your surroundings? That, too, could become a reality if cloaking research moves to the next level.

For now, the small-scale applications of cloaking are becoming closer to a reality.

One example Valentine provides is a computer chip that uses photonics, or light, to carry information on the chip. Electronics and other items on the chip do not allow light to pass through them. If a cloak was applied, the light-based chip would be able to carry information around the electronics and other items on the chip.

Although Valentine’s professional research has never really been focused on cloaking, he is still interested in making metamaterials out of dielectrics.

“My group right now is pursuing some of the other applications of metamaterials,” adds Valentine. “The idea with metamaterials is that you can create any optical property you want and can engineer it at will.”

Their current research involves making ultra-compact optical elements, such as a camera lens.

Valentine and his group are working on making a lens that is 100 nanometers thick, which is about the same size as a sheet of film or transparency.

The ultra-compact optics in the lens would eliminate the need for a large lens in a camera. Another application is in cell phone cameras in order to increase the quality of pictures taken on a phone.

“One of the keys in this research is that you don’t want the metamaterial itself to absorb a lot of energy,” says Valentine. “If you do want something to absorb, you want to put it in a semiconductor and then extract the energy from that material.”

Looking to future of metamaterials, it’s this type of application that may help increase the use of photovoltaics. With metallic metamaterials, there is an absorption loss issue. However, if researchers can figure out how to capture this loss and create photovoltages or photocurrents for energy conversion, these materials could help harvest that energy absorption loss from solar energy conversions.

Whether it’s a military application for cloaking drones or the next big architectural design movement, research into cloaking and invisibility using metamaterials has really only just begun.